Auto tape application machine with hot melt gluing system

Auto tape application machine with hot melt gluing system

Location:Bologna, Italy

Available quantity:1

Description

This is an integrated solution for the global cross-border e-commerce carton to paste, folding gluing boxes, and form. At present, it is aimed at special-shaped “zipper carton”, “cross-border mail box”, “post online shopping box” obtained a large market share, and completely solved the problems of abnormal bending. It has obtained paper box out of order, product loss and other problems. The machine is simple and convenient to adjust, and can be operated with no experience and simple training.

Friction Belt Feeder

This new design concept mainly focuses on irregular corrugated cartons. Horizontal feeding with the help of independent vibration motor completely solved the unsmooth feeding of irregular and bent boards.

Calibration Correction Device

Independent orientation, one side as the base to calibration the box direction which makes the tape sticking precisely. The roller design make the transport more stable. The upper presser and under board can be adjusted according to the products’ demand. This can keep the precision of sticking. Individual motor driving makes the machine running stably.

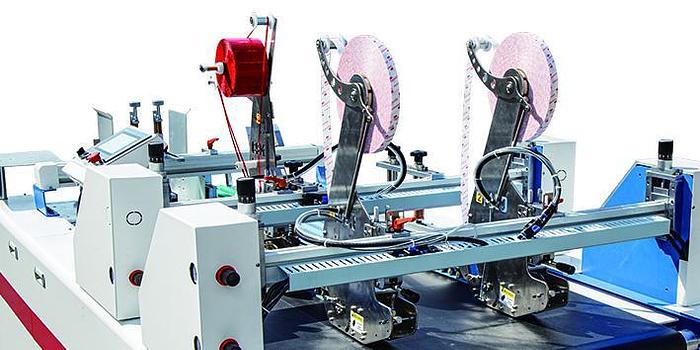

Tape Applicator

It is more humanity in adjusting and products changing. It is straight tracker in adjusting part. We self-developed 90 degree turning bracket is using on this machine. This technology decrease the dependability of the operators’ technical. Even without any experience, the operators can run it easily with simple training.

Hot Glue&Scraping System

The material cylinder melts the material after heating and melting, outputs the metering pump to the filter, then filters it to the spray gun through the hose, and realizes the spray by opening the solenoid valve.

Release Paper Feeder

The servo motor is used to drive the release paper accurately and quickly.

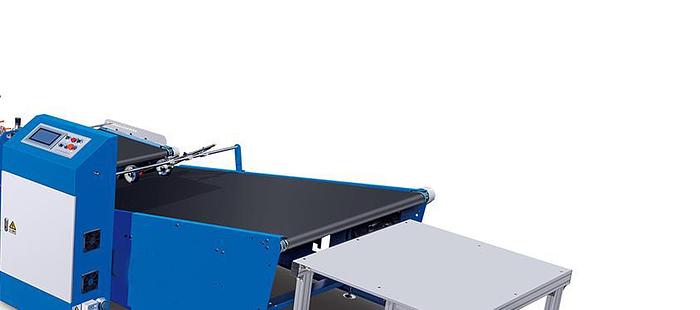

Conveyor Section

The import 2mm thickness belt is soft enough for protecting products from pressing damage. Stack collection structure prefect the products quality. These is a products counting option.

Electrical controller

Using the latest PLC controller system, equipped with European and Japanese international brand electrical control components, simple circuit control procedures, stable operation, low failure rate, convenient maintenance.

Specifications

| Manufacturer | BBS |

| Model | KS-1450 |

| Condition | New |

| Stock Number | 6258473 |

| Model: | KS-1450 |

| Material: | Over 300 g/m² cardboard,corrugated board |

| Open blank max: | 1450 mm x 1050 mm |

| Open blank min: | 300 mm x 300 mm |

| Working width: | 1050 mm |

| Conveyor speed: | 90 m/min (Depends on different boxes and tape type.) |

| Tape roll width: | 5 - 40 mm |

| Needed air supply: | min. 6 bar |

| Precision: | + / -1.5 mm (Depends on different boxes and tape type.) |

| Sticking style: | Vertical sticking. |

| Power required: | 3.2KW(380V AC 3φ 50HZ) |

| Form advance: | Automatic feeding |

| Weight: | Approx. 1800 KG |

| Machine size: | 5700*2450*1200 mm(L*W*H) |