SPOT UV 1450

SPOT UV 1450

Location:Bologna, Italy

Available quantity:1

Description

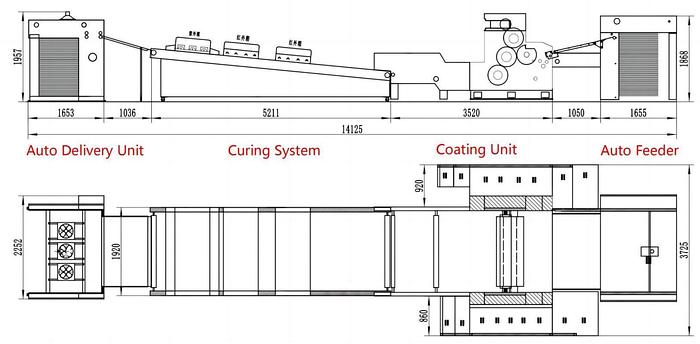

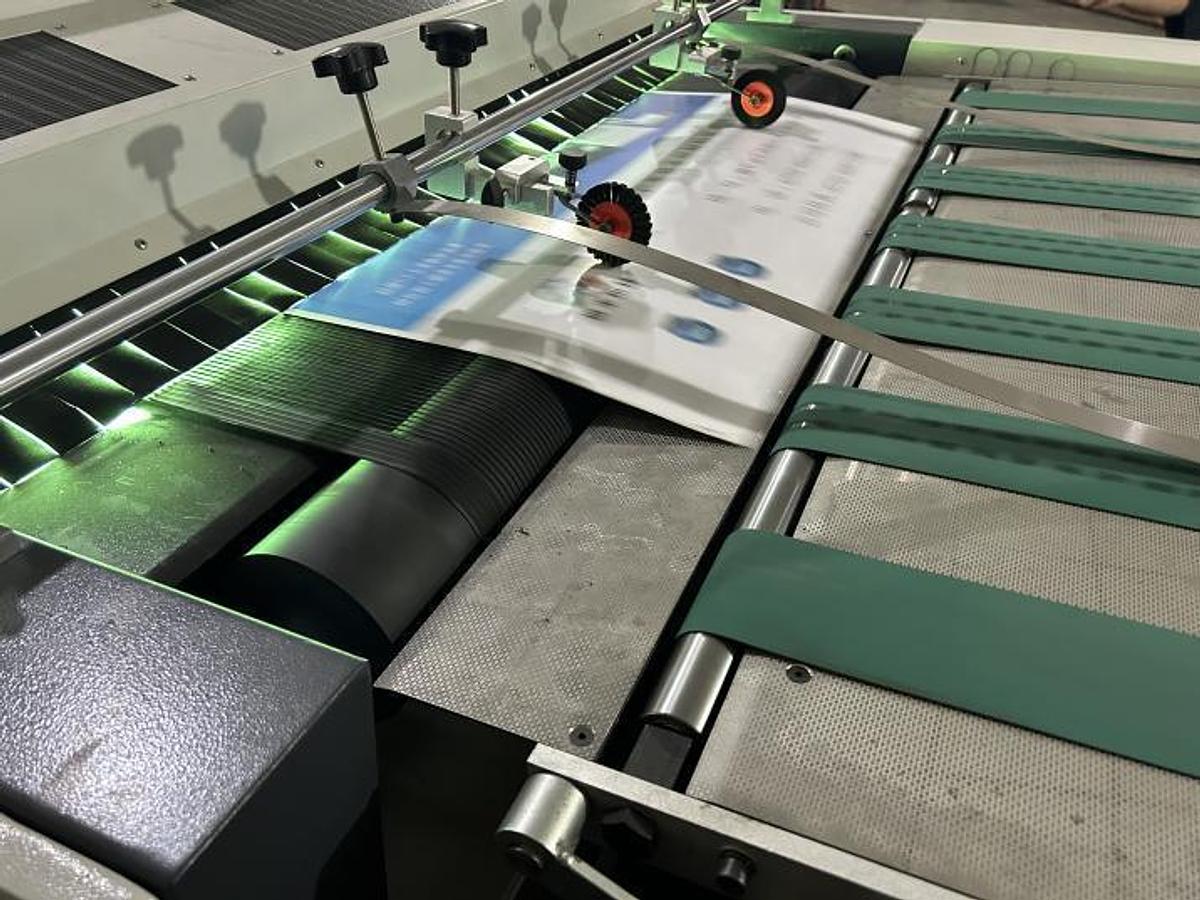

NSGZ High Speed UV Spot and full sheet oil Coating machine adopts upper-sway gripper-pass-sheet method to enable max speed up 8000 sheets/hour. UV curing system with Teflon conveying belt has characteristic of higher speed, precise orientation and UV curing higher efficiency and lower power consumption. After sheet traveling through UV coater and being transferred directly by Teflon belt, gripper can not be heated by high temperature from UV light, which prevent them from being damaged or deformed to ensure easy maintenance.

Consumables:

- Water base oil, UV oil

- Printing plate: Resin version for spot coating/Rubber plate for full sheet coating

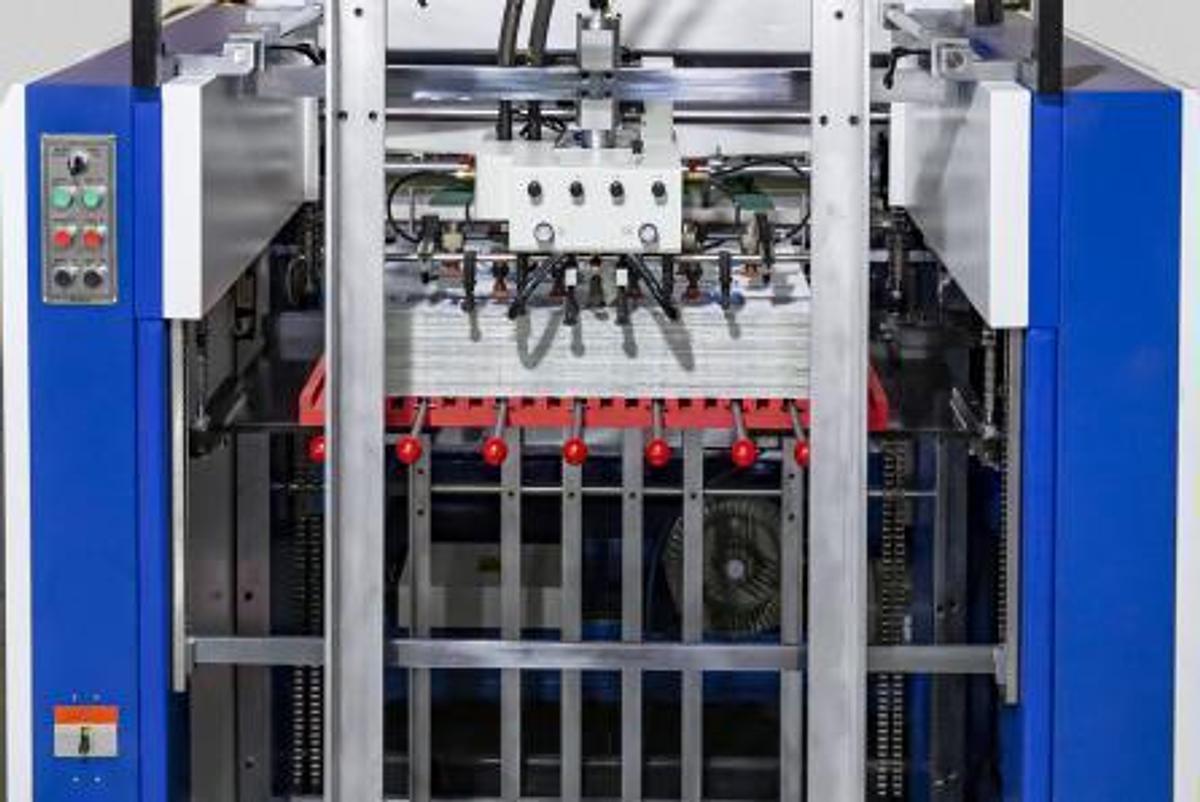

Automatic Feeder:

- High speed feeder with four sucking and four forwarding suckers can feed sheet smoothly, Maximum speed can reach 16,000 sheets per hour.

- The lifting and lowering of the paper stacking table is controlled by limit switches, which is safe and reliable.

- The air pump used is the BECKER Pump 80#, which is currently the most stable, durable and powerful air pump on the market.

- The fish-scale bridge paper feeding platform is equipped with high-strength suction to ensure smooth paper transportation

- Dual detection device

Sheet transferring:

- Upper swing sheet transferring method can transfer sheet smoothly at high speed to pressure cylinder exactly.

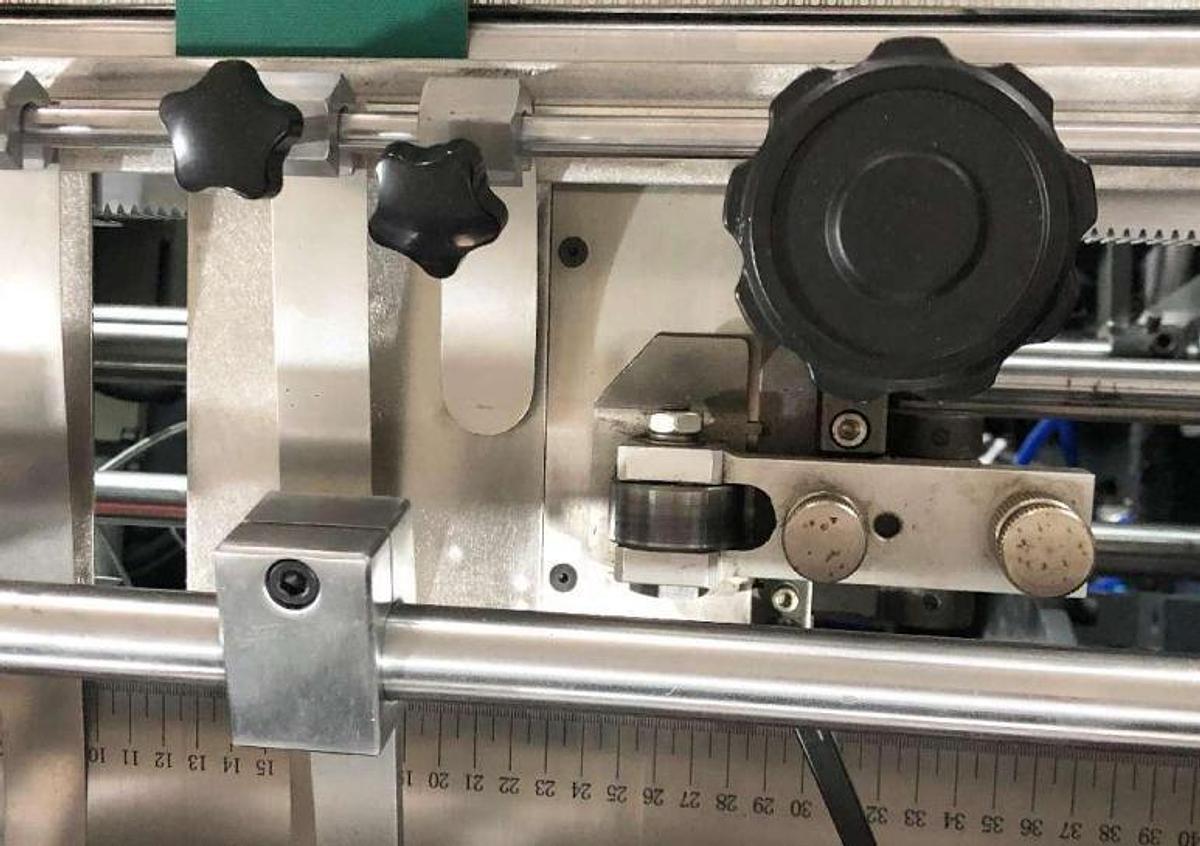

Host paper front gauge and side pull gauge device Introduction:

- Front gauge: ensures that the front end of the paper is aligned during transportation to ensure the accuracy of the glazing position. (This device is equipped with two photoelectric switches. If the paper breaks or tilts, the feeder will stop automatically.)

- Side gauge (left and right): adjusts the left and right positions of the paper to prevent deviation and ensure the accuracy of Spot coating.

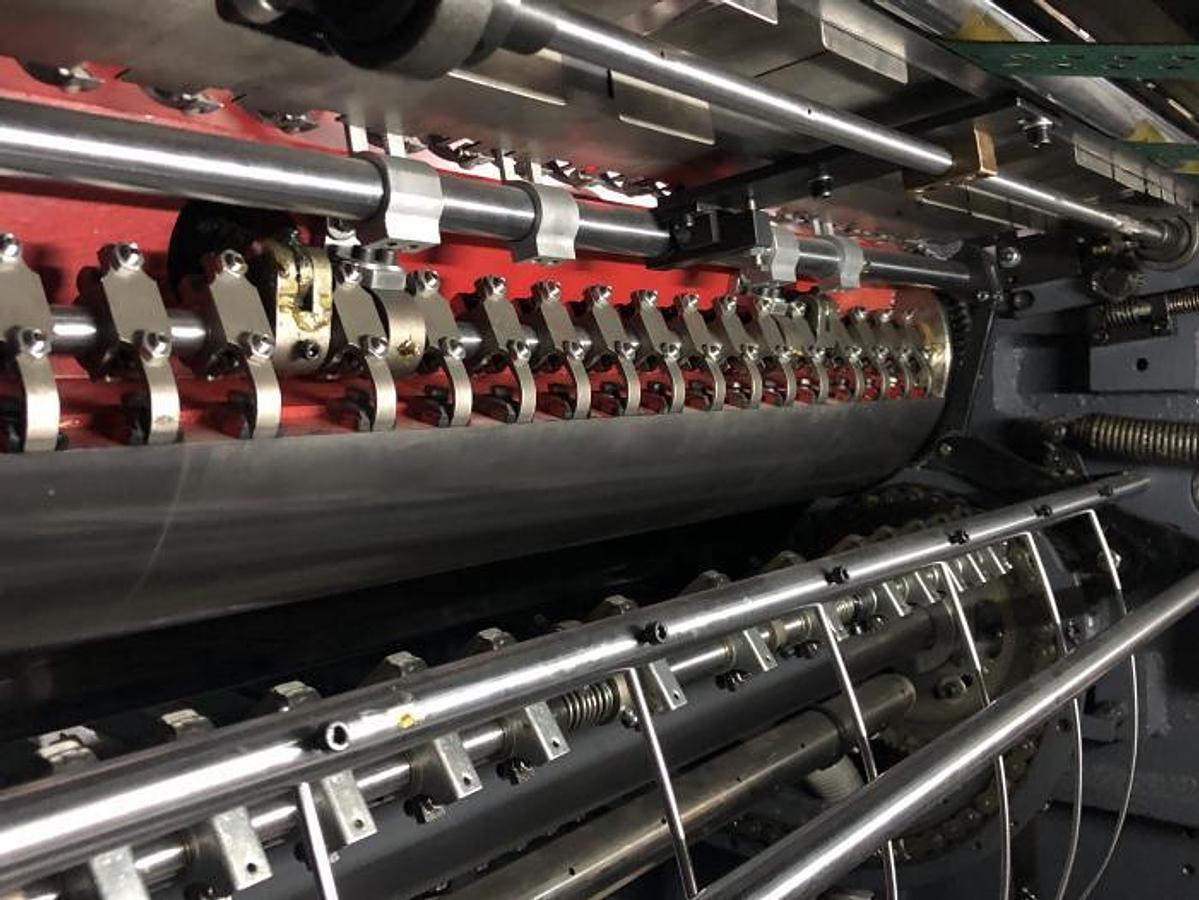

Host Ink Supply:

- Steel roller and rubber roller with metering roller reversing and doctor blade design control varnish consumption and volume to meet the demand of products and operate easily.(Varnish consumption and volume are determined by LPI of ceramic anilox roller)

Transferring Unit:

- After sheet is transferred from pressure cylinder to gripper,air volume blowing for paper can support and reverse sheet smoothly, which can prevent sheet surface from being scratched.

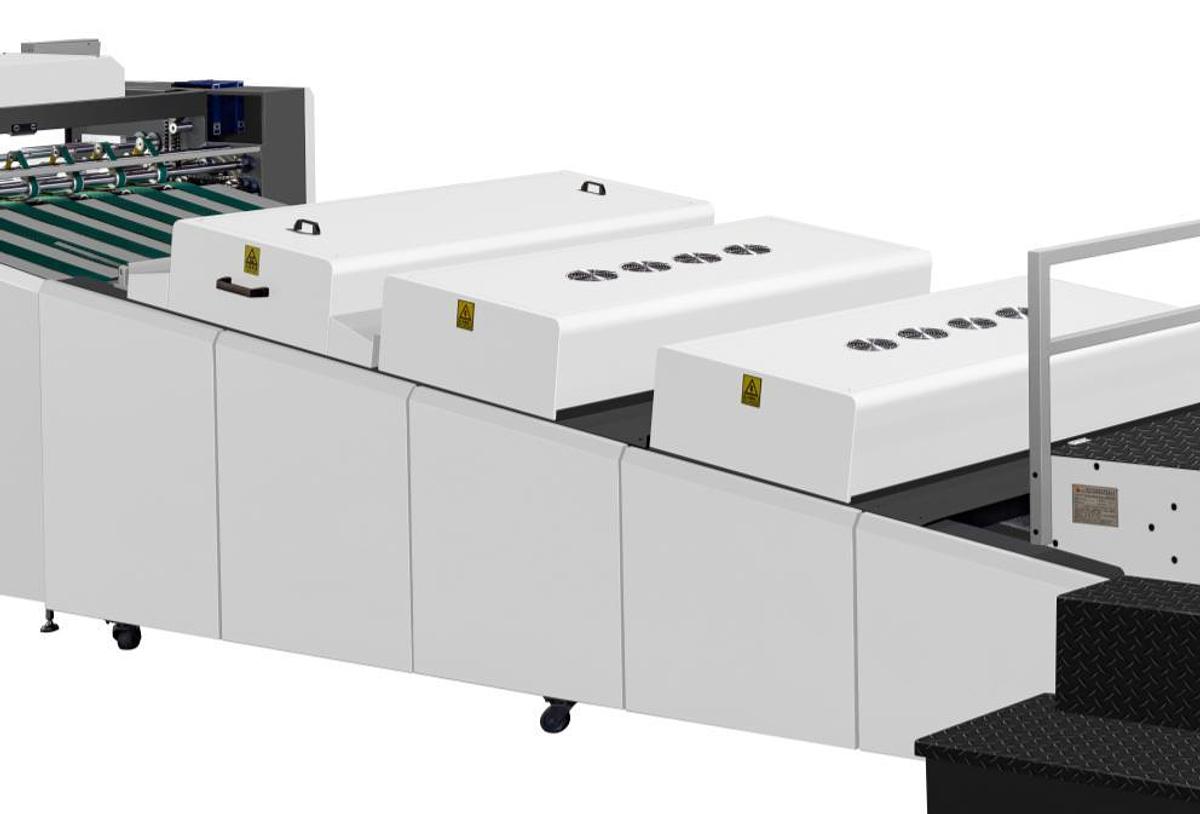

Dryer channel unit:

- This unit with double function, include UV dryer, IR dryer and hearing air device, which suitable for UV oil and water-base oil drying.

- Standard machine with 3 sets of UV lamps, total power is 27kw; 24 pcs of IR lamps, total power is 24kw;

Conveying Unit:

- Upper and lower conveying belt can form thin sheet to be curved for smoothly delivery.

- Paper jam detection system, if the paper delivery machine is jammed with paper, the bridge plate will open and reset after recovery

- Option: Air conditioning cooling

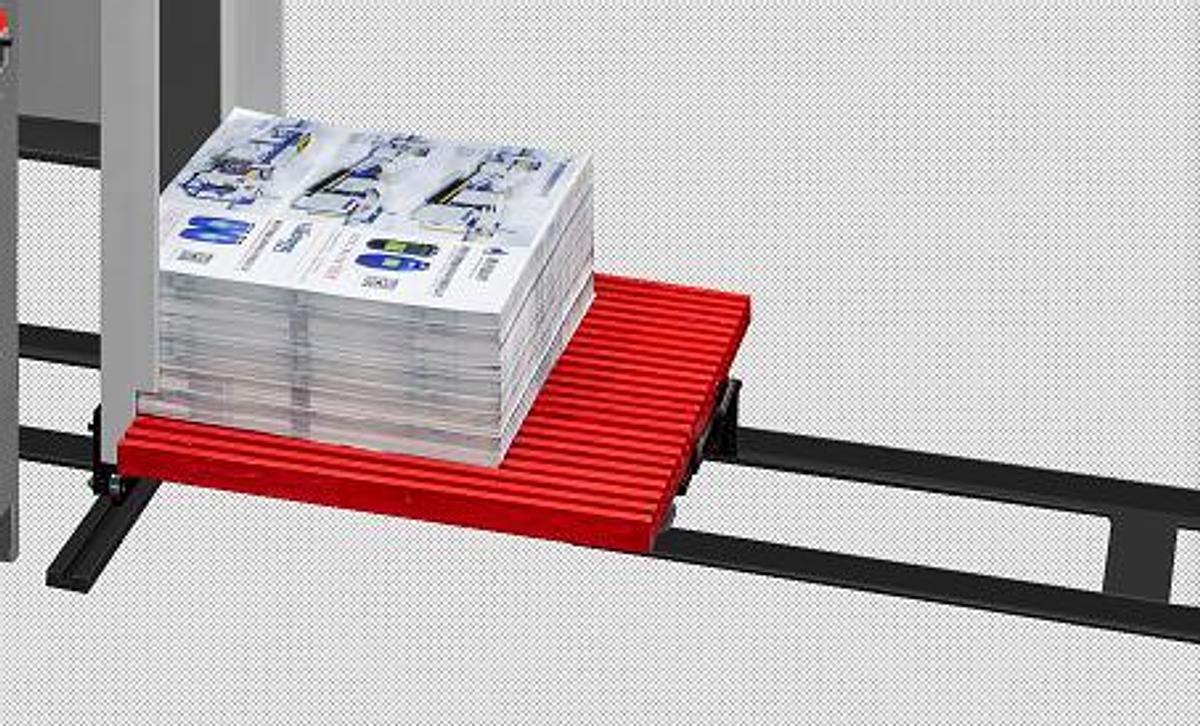

Sheet Delivery:

- Automatic pneumatic patting sheet controlled by photoelectric detecting sensor make sheet pile fall automatically and collect sheet neatly. Electronic control can take out sheet sample safely and quickly for inspecting.

- Option: Non Stop Delivery

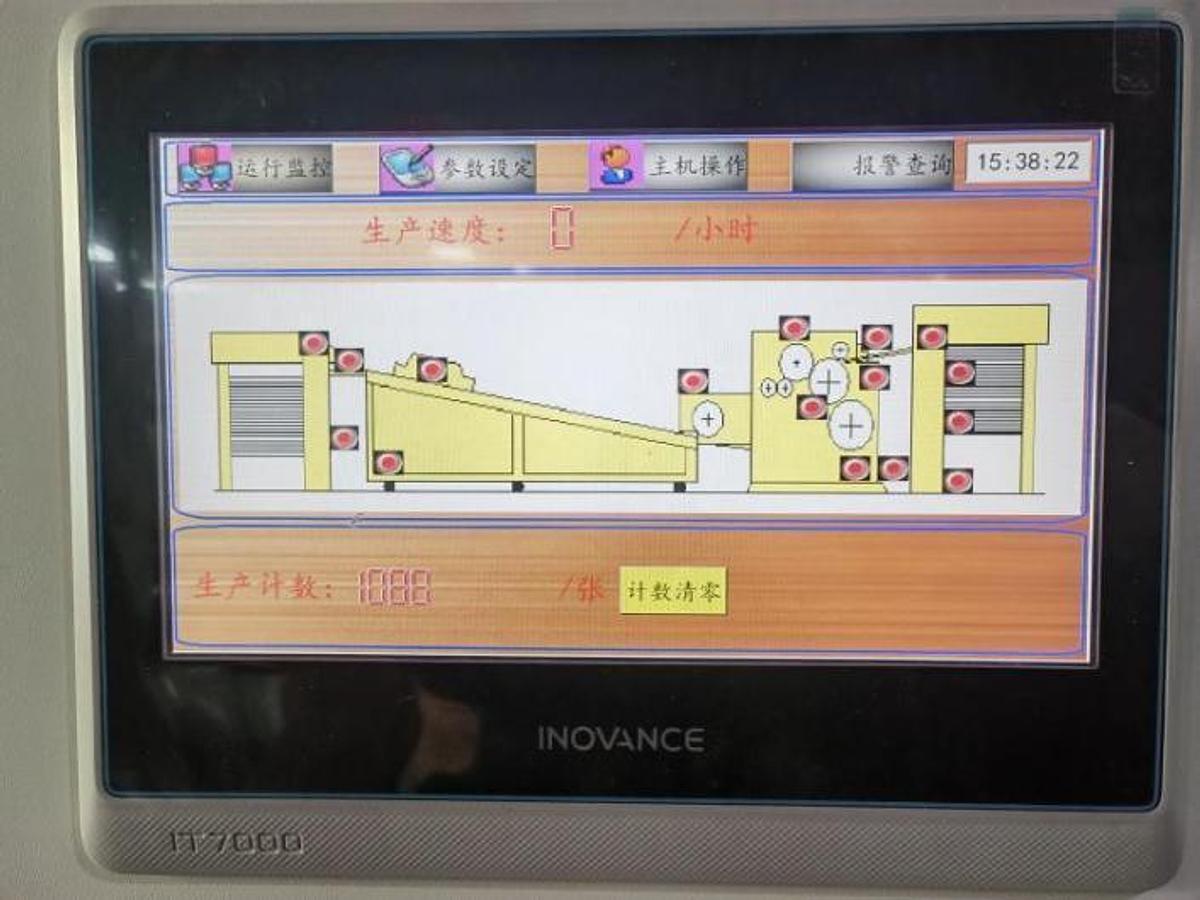

Touch Screen:

- 10 inch size touch screen which easy to read and operate, language with Chinese and English

- Option: 15 inch touch screen

OPTIONAL FUNCTION INTRODUCTION OF EACH PART:

- Axis-less feede, servo motor feeder: Pre-Loading cart& track: When the machine is running, the main pile of paper is working, and the operator arranges the next pile of paper on the pre-pile car, waiting for the main pile of paper to be completed, and then stops the machine. The paper stacking platen drops to the lowest position, the pre-pile of paper is pushed onto the paper stacking platen, the paper stacking platen rises, and the machine starts working again. Reminds: If with paper turning machine, no need choose the pre-loading option, using forklifts and pallets to load paper is more efficient.

- Ceramic roller doctor blade

- Ceramic rollers have a long service life and can accurately control the weight of oiling

- The chamber scraper system seals the oil inside to prevent dust, dirt or other particles from entering the oil, and it has two steel scrapers for even oiling, fuel saving and more delicate

- Air conditioning cooling: 3 Horse Power 2.2 KW industrial air condition, which for reducing paper temperature, prevent oil from discoloring at high temperatures, and ensure adequate drying

Feature Highlights:

- Spot area and full-sheet dual-purpose machine;

- Spot UV coating has clear effect, precise edge and no oil spill;

- The mechanical structure is optimized and runs smoothly, which can maintain consistent coating quality for a long time;

- It can be used for various paper types, including coated paper, cardboard, etc., to meet the needs of different printed products;

- Touch screen control, flexible parameter adjustment and simple operation;

- Optimize ink and UV lamp energy consumption, improve curing efficiency and reduce material waste.

Specifications

| Manufacturer | BBS |

| Model | NSGZ-1450S |

| Condition | New |

| Stock Number | 6258472 |

| Coating Registration Accuracy: | ±0.2mm |

| Max.Sheet Size: | 1100mm×1450mm |

| Min.Sheet.Size: | 350mm×460mm |

| Max.Coating Area: | 1090mm×1440mm |

| Sheet Thickness: | 80-600gsm |

| Production Speed: | Up to 8000 sheets/hour (Depending on sheet weight, size and quality) |

| Oiling thickness: | 0.015mm ~0.06mm |

| Viscosity range: | 150~250CPS |

| Max feeding paper pile height: | 1200mm (not include 100mm tray) |

| Max collecting paper pile height: | 1200mm (not include 100mm tray) |

| Machine Weight: | 1200kg |

| Dimension(L*W*H): | 16200mm×3725mm×1957mm |

| Power Required: | 66.8Kw (solvent base) /58.6Kw (water base) |

| Air Compressor: | 4KW, 0.8MPA, 0. 6m3/min |

| Wire: | 2 sets (16mm2 *3 Live wires+ 4mm2 *1 Ground wire+ 4mm2 *1 Zero wire) |

| Optional Device: | Axis-less feeder <> Ceramic roller chamber doctor blade <> Ceramic Roller with Normal Doctor Blade <> Pre-Loading cart & track <> Air conditioning cooling |