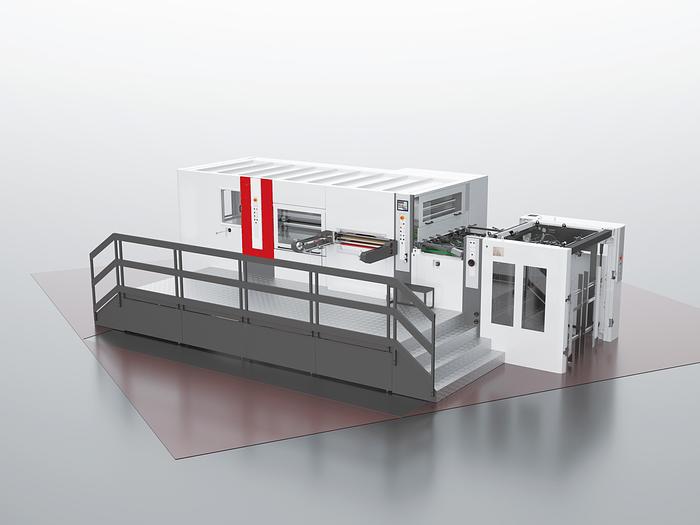

Diecutter + Foil 1450T

Diecutter + Foil 1450T

Location:Bologna, Italy

orCall +359 2 492 9330

Description

1. Feeding Unit

- Pile tray with handle allowing manual lateral correction of the pile during production

- German design automatic feeder with non-stop feeding offer by MABEG SHANGHAI MACHINERY-MMS

- Stream-wise feeding system with highest speed at 125 sheets per minute

- 4 suction cups each for lifting paper, five suction cups for moving paper

- Height and angle of suction heads are easily adjustable.

- 3 electronic safety devices preventing feeder pile from over ascending

- Micro-adjustment is available for transversal positioning of pile table

- Lateral blowing system enhances paper separation

- Precision double-sheet detector

- High pile design allows maximum pile height up to 1700mm

- The speed of the feeding belt is adjustable

- Easy changeover of pull and push side guides simply by turning a bolt without the need of removing and replacing complete side guide

- 2 front guides with micro-adjustment and the side guide is adjustable by wheel handle

- Side and front guides are with precision photocells, which can detect dark color and plastic sheet. The sensitivity is adjustable

- Single position engagement pneumatic operated mechanical clutch insures the first sheet after every re-start of machine is always fed to front lays for easy, timesaving and material saving make ready

- Photoelectric detector with automatic stop system on feeding table in case of paper jam

- Separate drive controls of main pile and auxiliary pile.

- PLC and electronic cam for timing control

2. Diecutting Unit

- Siemens main motor controlled by Schneider inverter control

- Micro-adjustment of cutting force by worm gear driven by motor and controlled by touch screen

- The pressure accuracy can be up to 0.01mm

- Crankshaft made of 40Cr steel

- Machine frames made of Q235-A Steel, upper and lower platens made of HT300 ductile iron with resin-coated sand with Meehanite Die Cast Iron Technology

- Accurate positioning of Cutting chase controlled by precision photocell sensors with automatic check lock device

- Cutting chase turnover device

- Overload protection device with torque limiter for the highest safety of operator and equipment

- 7 sets of gripper bars with grippers made of lightweight and durable aluminum alloy with ultra hard coat and anodized finish ensure accurate and consistent paper registration

- After long run test and delivered in pairs, main gripper, chain from Subaki, Japan

- High pressure index drive system for gripper bar positioning control

- Special designed gripper bar lock for compensation to insure accurate paper registration

- Pneumatic lock-up and release of cutting chase

- Cutting plate with aluminum base to protect the lifetime of the cutting plates and to reduce the noise when diecutting

- Centerline system for quick job changeover

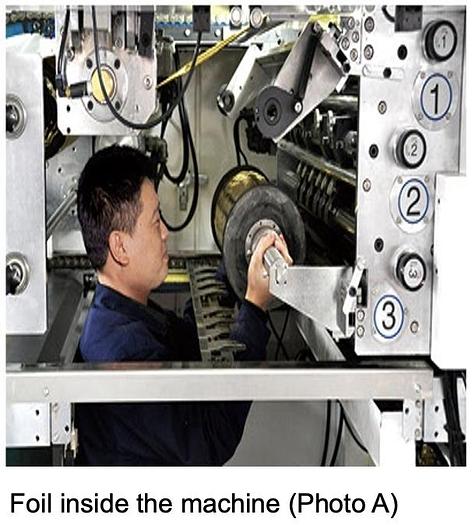

3. Foil Stamping Unit

- 2 sets of individually controlled programmable foil pull rollers in Longitudinal direction driven by Panisonic servomotors

- 12 individually controlled heating zones , using intubation heating system ,with a tolerance within ±1°C

- Automatic foil feeding device for the ease of loading foil rolls

- 1 set of ductile iron honeycomb chase and locking device for dies

- Dwell time device is available for big area stamping

- Air blowing separation device is available

- waste foil will be collected Inside the machine automaticlly.

4. Delivery Unit

- Safety photoelectric devices preventing over-ascending and over-descending of delivery paper pile.

- Adjustable depressor brush helps unloading paper from grippers and piling up paper

- High pile design up to 1445mm

- Automatic auxiliary belt table available for non-stop delivery

- Feeder movement and speed control can be adjusted in the delivery unit.

5. Electric Parts, Operator Interface and Safety Detector

- The high speed Japanese industrial Omron PLC system

- Omron operator interface with touch screen

- Omron Electronic cam switch and encoder

- Electronic detectors, micro switched and photoelectric cells controlled by PLC on entire machine

6. Automatic Lubrication System

- Automatic oil pump and distribution system for entire machine with preset timer

- Lubrication oil distribution for gripper chains with individually controllable valve for each chain

7. Safety Devices and Quality Approval of Components

- All electronic and electrical parts are CE approved

- Overload protector for the protector and equipment

- Gripper chain clutch for the protection of gripper bars

- Emergency stop buttons on entire machine for quick and easy access

Specifications

| Manufacturer | BBS |

| Model | 1450T |

| Condition | New |

| Stock Number | 6258449 |

| Maximum sheet size: | 1450×1150mm |

| Minimum sheet size: | 650×450mm |

| Maximum diecutting size: | 1430×1130mm |

| Maximum Stamping Size: | 1430*1130mm |

| Inside chase: | 1510×1215mm |

| Maximum speed: | 5500 sheets/hour |

| Maximum Stamping speed: | 4000 sheets/hour |

| Maximum pressure: | 400 tons |

| Sheet thickness: | 200g/m2 ~ 2000gsm/5mm B flute corrugated paper |

| Heating Zone: | 12 Zones |

| Programmable Feeding: | 2 Unwinds Shafts - Longitudinal Unwinder |

| Total Weight: | 33Ton |

| Total power: | 70kw |

| Dimension (L × W × H): | 9560×5900×2800mm |

| Delivery time: | About 6 months after receipt of down payment |