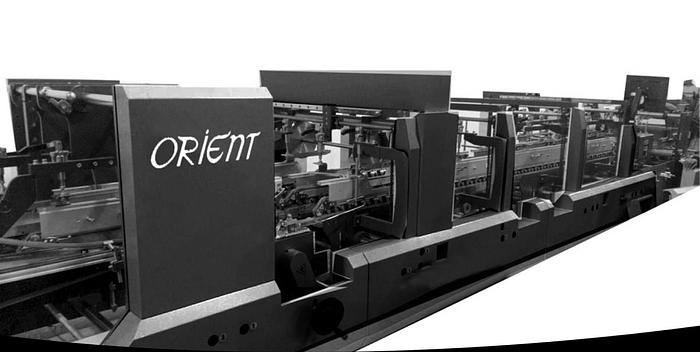

Folder gluer 650

Folder gluer 650

Location:Bologna, Italy

Description

Our standard configuration includes:

- Lock bottom

- Side pasting

- 4 corner device

- Pre folding section

- Suction feeder

- Grinder

*Point glue are excluded as depends on customer requirement

Every folder-gluer in the X-Press range is meticulously designed to deliver exceptional performance, superior product quality, and unmatched reliability. Orient X-Press Fold is available in multiple versions, enabling the production of cartons ranging from simple to highly complex designs, in sizes ranging from tiny to large, and accommodating short to long run lengths, all with the highest levels of automation.

Experience the reliability, precision, and versatility of this folder-gluer that goes beyond your expectations. With Orient X-Press Fold, you can effortlessly create a wide range of box styles using different materials, achieving incredible speeds of up to 400 meters per minute. Operating the folder-gluer is easy, ensuring consistent and superb quality in every end product.

As an optional feature, Orient X-Press Fold can be equipped with Braille embossing capability. This device ensures box compliance by allowing you to emboss Braille onto carton boxes, including images, letters, and numbers. It guarantees pharmaceutical conformity, complying with Braille Norm EN-15823, and offers high-quality, long-lasting Braille with unrivaled efficiency, all achieved in an extremely fast in-line process.

7 KEY FUNCTIONS THAT LEAD TO THE X-PRESS FOLDS' WORLD CLASS PRODUCTIVITY:

- The orient quick feed system for efficient and rapid substrate feeding

- The around breaking auto correction system ensures and quality in alignment

- An all encompassing pro folding system that ensures consistency at high speeds

- A cutting edge lock bottom section which provides great flexibility and ease of operation

- A smooth and progressive folding section

- A fully automated trombone section with complete HMI controls for a seamless production experience

- A highly reliable and constant delivery section

The X-Press fold is a fully automated machine with a state of the art man- machine interface. This interface allows the machine to house multiple types of automation and synchronize the in order to achieve improved ROI's and high speeds with strict quality control checks. Our interface is user friendly and is focused on making the experience intuitive for any operator to easily use.

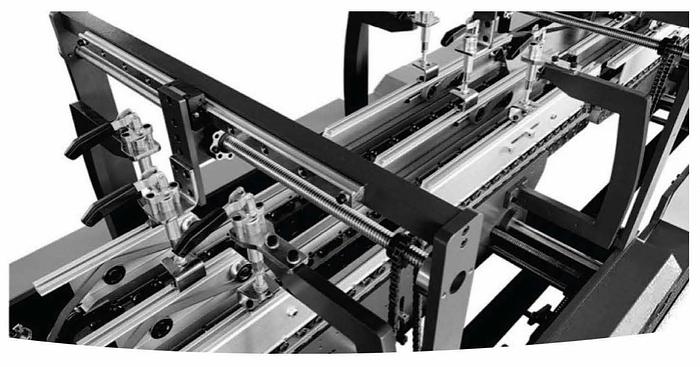

1. Feeding Section:

- Independent motor driving system and synchronized feeding with the main motor.

- Seven 30mm thickened paper feeding belts and metal plates of 10mm for adjustment on the width.

- Embossed driving wheel drives paper delivery belts: back plates on the left and right sides can move or be adjusted per product dimension.

- The Feeder is equipped with 3 paper-delivery blades which can adjust the asymmetric length per actual material.

- The vibration devices with the motor provide fast, simple, continuous, automatic and accurate feeding.

- The Feeder can be stacked with 400mm paper, ensuring smooth and steady feeding

- Operators can control the feeding switch in any operational area.

2. Alignment section:

- Auto-correction of paper/sheets from the Feeder ensures feeding accuracy.

- Adjustable press drive fit for various thicknesses of paper/sheets.

3. Pre-folding section:

- The specific design ensures 180 degrees on 1st crease and 165 degrees on 3rd crease, making the box easier to extend 4/6 corner boxes bottom-locking system

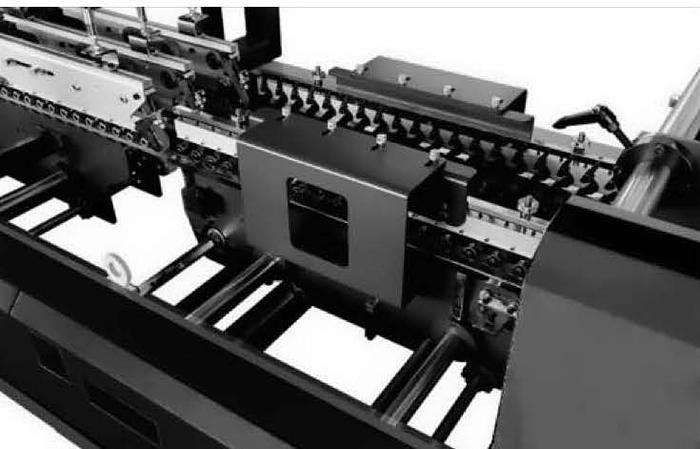

4. Lock the bottom section:

- Equipped with bottom lock combination/adjustment, with a n ideally flexible design that ensures fast and easy operation.

- A sectional belt feeder with a special design, flexible and adjustable per product requirement without tightening or loosening the belt.

- Stainless steel lower gluing units on t h e left and right sides with big volumes

- that can be adjustable, stable and easy to maintain; a 4mm gluing wheel can be optional

- Bottom folding is finished with 4 sets of bottom-lock devices.

- Bottom belt 30mm, upper belt 20mm; upper plates move up and down like came to be fit for various thicknesses of bards.

5. Final Folding:

- 2nd crease 180-degree, 4th crease 180 degree.

- Specifically designed to adjust belt feeding speed separately to correct box embryo running direction and ensure straight feeding.

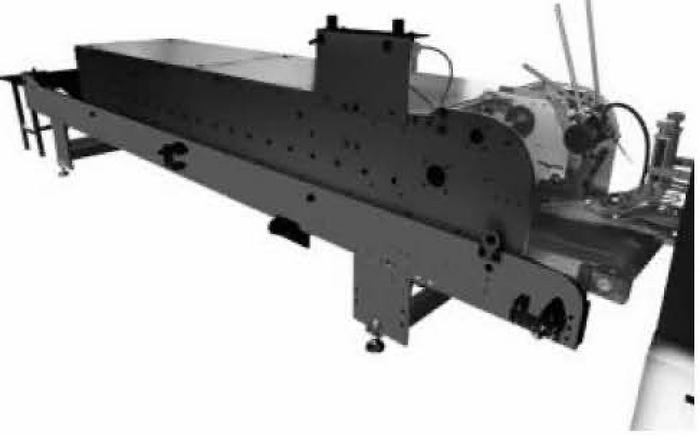

6. Trombone pressing section:

- Auto-collecting of paper boards and water spray by a photoelectric counter

- Paper-jam inspection device

- Adjustable upper and lower belts for easy and simple operation

7. Press conveyor section:

- Movable stacking belts of 2 boards on left and right, adjustable in online production per stacking requirement of the boxes to improve efficiency.

- Special and extra sponge belts for pressing the conveyor part of the box’s piles.

- Air-pressed easy adjustment to ensure even pressure of gluing and folding.

- Synchronized in proportion with t h e main motor in automatic mode to improve stable stacking

8. Main standard parts:

- 1 set of Toolbox

- 1 set of Counting sensor

- 12 pcs Balance Washer

- 1 pc Horizontal tube ---15M

- 1 set LCD Display

- 1 set Remote Controller

Specifications

| Manufacturer | Orient |

| Model | X-Press fold 650 |

| Condition | New |

| Stock Number | 6258420 |

| Max. sheet size: | 650X700mm |

| Min. sheet size: | 100X50mm |

| Applicable paper: | Cardboard 250g-800g - corrugated paper F、E |

| Max. belt speed: | 450m/min |

| Machine length: | 15800mm |

| Machine width: | 1350mm |

| Machine height: | 1450mm |

| Total power: | 18.5KW |

| Max. air displacement: | 0.7m³/min |

| Total weight: | 5500kg |