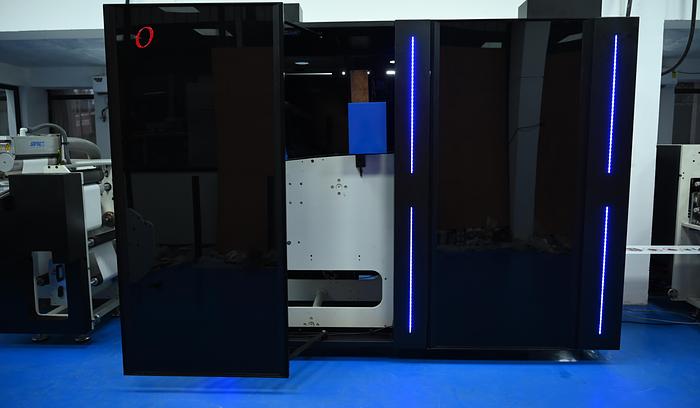

Orient JET L&P Series

Orient JET L&P Series

Location:Bologna, Italy

Description

This machine is customizable in format and configuration. Each of our offerings is customised to our customer's specific needs.

- Orients proprietary Orient jet ink delivery system provides a more efficient use of ink leading to lower opex along with an ability to print on almost any substrate known to man.

- Orient has a proprietary in house software ensuring efficiency at every stage

- Fully backward integrated where everything is made in house so the press is fully customisable and due to our history we ensure excellent metallurgy and market leading web handling

- Full service and consumables team and our presses operating expense is extremely low and value for money.

- A full backward integrated in house manufacturing unit and a full service and support staff across the country.

Orient Jet L&P Series: High-Speed Inkjet Printing Press

Top-of-the-Line Performance

Offers high-speed inkjet printing capabilities

Available in 7 to 8 color options

Versatile Customisation

Multiple inline features

Tailored for diverse printing and packaging requirements

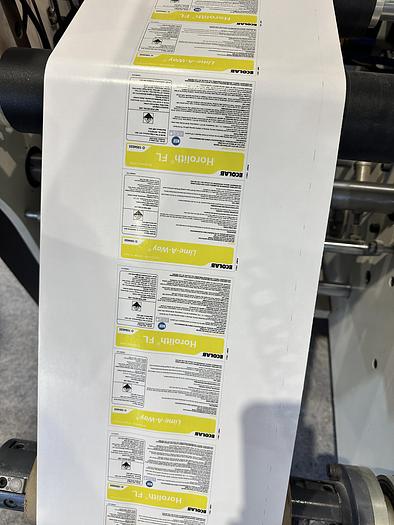

Ideal for Labels and Packaging

Specifically designed for label and packaging applications

Market-Leading ROI

Exceptional return on investment

Enhanced Productivity

Streamlined operations for superior efficiency

User-Friendly Design

Easy to operate, promoting seamless integration into workflows

Why Digital Solution in Label Printing?

- Rapid Production Turnaround: Emphasis on minimising production lead times to meet market demands.

- Brand Requirement for Personalised Communication: Necessity for tailored 1:1 communication strategies to enhance brand engagement.

- Declining Market Run Lengths: Observing a trend towards shorter print runs in the marketplace.

- Ongoing Demand for Short-Run Jobs: Continuous requests for short-run projects from end customers.

- Personalization Needs: Increasing demand for personalized printing solutions to cater to diverse consumer preferences.

- Compliance with Variable Data Printing (VDP) Requirements: Adherence to specifications for effective variable data printing.

- Track and Trace Capabilities: Implementation of systems for tracking and tracing printed products throughout the supply chain.

- Complementary Solutions to Flexo Printing: Digital printing serves as a supportive technology to meet emerging demands in the industry.

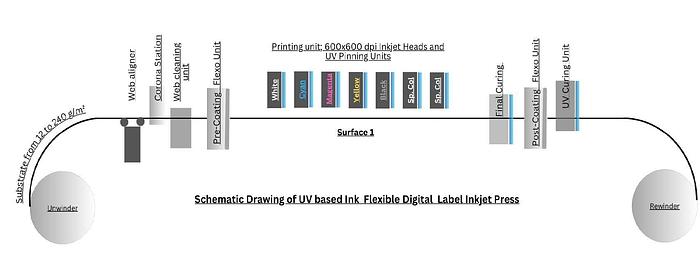

Overview of presso configuration

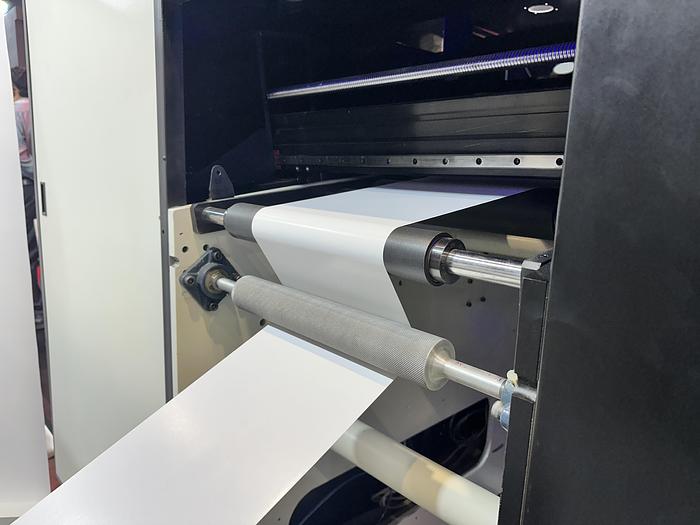

1. Unwind Station (Servo Driven)

- Auto tension control system by program-based calculation for precise tension control

- Tension range: 20-300N

- Pneumatic roll lifter for loading substrate

- Reel locking by 3 inch " air expanding cantilever shafts

- Active unwinder driven by servo motor

2. Splice Table

- Provision for quick substrate changeover

- Two pneumatic clamps to hold new reel and threaded substrate

3. Corona Treater

- Enhances substrate bonding with ink/coating by increasing surface density

- Cassette type with 2kW power, controlled remotely

4. Web Guide

- Edge positioning type with twin roll aligner and actuator

- Ultrasonic sensor

- Auto/manual correction displacement of ±14mm

- Manual sensor positioning

5. Web Cleaner

- Cleans both sides with cleaning roll and static discharger

- Removes lint/dust from substrate before printing

- Prevents ink contamination and anilox clogging

6. In-feed

- Nip and pressure roller assembly with pneumatic cylinders

- Isolates tension between unwinder and first station

- Tension range: 20-300N maintained by load cells

7. Pre-Printing Coating/Flexo Station

- Quick-change petal design for easy plate/cylinder

- changes

- Ceramic anilox roller (per chosen LPI)

- Ink tray with furnishing roller

- Doctor blade assembly

- Plate cylinder

8. Digital Printing Unit

- 600 x 600 dpi printheads from Kyocera Japan using Piezo DoD Technology

- LED Pinning after every Color Unit

- LED Curing

- Automatic printhead cleaning system

- Auto-Capping of printhead

- Air cooled pinning and curing

- Automatic variable ink drop size from 4 pl to 14 pl

9. Outfeed

- Nip and pressure roller with pneumatic cylinders

- Separate tension zone from last print to rewind

- Tension range: 20-350N by load cells

10. Post-Printing Coating/Flexo Station

- Quick-change petal design for easy plate/cylinder changes

- Ceramic anilox roller (per chosen LPI)

- Ink tray with furnishing roller

- Doctor blade assembly

- Plate cylinder (buyer's chosen sizes)

- LED Curing11. Rewind Station

- Auto tension by program calculation

- Tension range: 20-350N

- Pneumatic roll lifter

- 3" air expanding cantilever shaft reel locking

- Active servo rewinder

12. External RIP with Server

- RIP with Imposition and limited VDP capability from Arden

- Print Server from HP/Dell

- Workflow with Print Server and Color Management (Optional)

Specifications

| Manufacturer | Orient JET |

| Model | L&P Series |

| Condition | New |

| Stock Number | 6258416 |

| Max Printing Width: | customisable |

| Print Method: | UV Inkjet / Aqueous Inkjet (Optional) |

| Color: | Wh+ C+M+Y+K (optional Orange, Violet, Special Color) |

| Printing Resolution: | 600 X 600 dpi |

| Max Roll Feeder / Winder Diameter: | 800 mm |

| Substrate: | Paper/Polyester PVC/PP/PE/PETG/BOPP/Foil/Synthetic |

| Substrate Handling Capability: | 12 to 240 microns |

| Registration: | Auto (both circumferential and lateral) |

| Printing Speed: | 60 mtr/min (speed may drop or increase depending upon the media) |

| Compatible file formats: | PDF/ PDF-VT/PPML |

| Operating conditions: | 24 Degrees, 46% Relative Humidity |

| Dimension: | 5407 x 1788 x 2161 in mm |

| Delivery time: | 3 months |