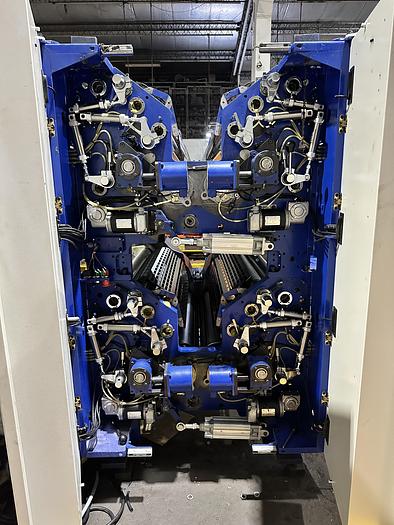

(55) - ORIENT, Super Web offset coldset Newspaper press

(55) - ORIENT, Super Web offset coldset Newspaper press

Location:Bologna, Italy

Description

Orient Super is a single width Single circumference web-offset press with a speed upto 30000 copies per hour for high quality newspaper printing tabloid printing book printing and semi-commercial products. The printing modules available for Orient Super (30000 copies per hour) are Mono Unit with Integral Reel stand, 3-Colour Satellite, AND 4 High Tower.

The Orient Super is a household name in the commercial printing sector and one of the most prolific presses of its kind.

With over 20,000 printing units supplied worldwide TPH enjoys strong relationships with some of the most distinguished and reputed commercial printers, publishers, and news houses in the world.

The Orient super is one of the best known presses in the offset world today and at its speed is a global market leader. Its reliability and efficiency are to this day unmatched.

KEY FEATURES: - Lever-type swing-down ink fountain with overrides for ink fountain roller - Dynamically-balanced Hard Chromium plated plate and blanket cylinders - On the nose, slit or spring-type plate lock-up system Electro- mechanical web-break detector - Centralised oil pressure lubrication for drive gears - Provision for printing up to 4 colours on both sides of one web, or 2 colour on both sides of two webs, or single colour on both sides of three webs - Running circumferential register for loading side plate cylinders - Variable-speed motorised dampening - Centralized water circulation system - PU Covered ink vibrator roller - Antiset web transfer grater roller

4 - HIGHTOWER

- Lever-type swing-downink fountainwithoverrides for ink fountain roller

- Dynamically-balancedHardChromiumplatedplate andblanket cylinders

- Onthe nose, slit or spring-type plate lock-upsystem.

- Motorizedside register systemforbothplate cylinders, onthe run

- Infra red web break detector• Safety guards

- Centralizedoil pressure lubricationfor drive gears

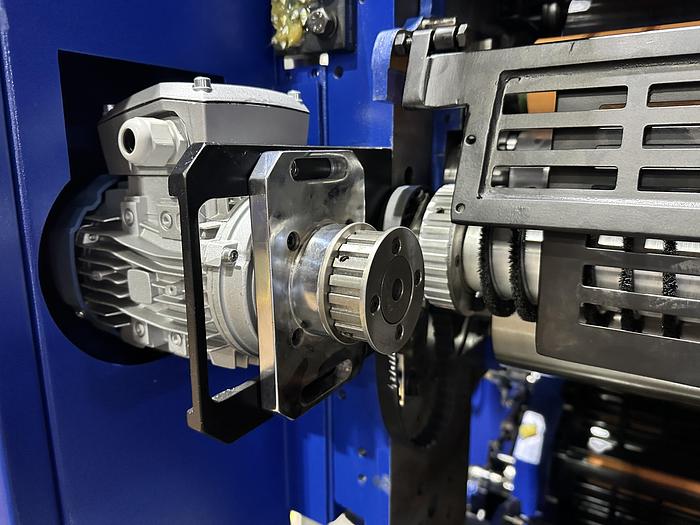

- Provision for printing 4 colours on both sides of one web, or 2 colours on both sides of two webs, or single colour on both sides of three webs •Heavy-Duty timer belt drive for 4 stack units

- Onthe runmanual adjustment for registration of 4 colours oneachside ofweb

- Motorized running circumferential register for loading side plate cylinders

- Variable-speedmotoriseddampening • Centralizedwater circulation system

- PUCoveredink vibrator roller• T-Bar blanket lock upsystem•Antiset-webtransfer grater roller

- Pneumatic on /off for Main impression/Ink feed/Ink form & Damper form • Brushmist Dampening System

- Cable management system

OPTIONS

- Heavy dutyCompensator

- Pillar clutchoneither side of 4Hi

- Automatic grease lubrication for operating side bearing and bushes

- Spray Dampening

- AC drive

- Narrowgap blanket cylinder

- Centralized water circulation system with chiller

- Solid stainless steel plate and blanket cylinders

- Hardened and ground bushes in frame for plate andblanket cylinder sleeves

MONOUNIT

- Lever-type swing-down ink fountain with overrides for ink fountain roller.

- Dynamically-balanced Hard Chromium plated plate and blanket cylinders.

- On the nose, slit or spring-type plate lock-upsystem.

- Motorized side register system for both platecylinders,on the run.

- Infra red web-break detector

- Pneumatic on /off for Main impression/Ink feed/Inkform & Damper form.

- Safety guards

- Centralised oil pressure lubrication for drive gears.

- Provision for printing 2 colors on same side of web(direct litho).

- Variable speed motorized dampening

- Centralized water circulation system

- PU Covered ink vibrator rollers

- T-Bar blanket lock up system

- Brushmist dampening System

- Cable management system

OPTION

- Motorized RCR for loading side plate register

- Heavy duty compensator

- Reel lifters (pneumatic control)

- Clutch on either side of unit

- Automatic grease lubrications for operating side bearing and bushes

- Auto reel changers

- Narrow gap blanket cylinder

- Centralized water circulation system with chiller

- Solidstainless-steel plate andblanket cylinders*

- Hardened and ground bushes in frame for plate and blanket cylinder sleeves.

- AC drive

3 - Colour satelliteUnit

- Lever-type swing-downink fountainwithoverrides for ink fountainroller

- Dynamically-balancedHardChromiumplatedplate andblanket cylinders

- Stainless steel, balancedmainimpressioncylinder

- On the nose, slit or spring-type plate lock-upsystem

- Motorized side register system for all plate cylinders on the run

- Motorized running circumferential register on two plate cylinders

- Safety guards

- Centralized oil pressure lubrication for drive gears

- Provision for printing 3 colors on one side of web or 2 colors on one side and 1 colour on other side of web

- Heavy-duty compensator

- Variable-speed motorized dampening

- Centralized water circulation system

- PU Coveredink vibrator roller

- T-Bar blanket lock up system

- Brushmist dampening system

- Pneumatic on /off for Main impression/Ink feed/Ink form & Damper form Infra red web break detector

- Cable management system

OPTIONS

- Automatic grease lubrication foropratingside bearings

- AC drive

- Narrowgap blanket cylinder

- Centralized water circulation system withChiller

- Solidstainless-steel plate andblanket cylinders*

- Hardened and ground bushes in frame for plate and blanket cylinder sleeves.

Specifications

| Manufacturer | Orient |

| Model | Super |

| Condition | New |

| Stock Number | 6258448 |

| Cut-off: | 508mm; 533mm; 546mm; 560mm; 578mm; 630mm |

| Printing Speed: | 30000Cph |

| Paper Width: | 660-889mm |

| Reel diameter (Max.): | 1070 mm(42”) |

| Printing Plate Width: | 890 mm |

| Printing Plate Length(gripper): | 516mm; 541mm; 554mm; 568mm; 586mm; 638mm |

| Printing Plate Length Unbent (Slit): | 539mm; 563mm; 577mm; 591mm; 609mm; 661mm |

| Printing Plate thickness: | 0.30/0.28mm |

| Rubber Blanket width: | 889mm |

| Rubber Blanket Length (T-Bar): | 556mm; 581mm; 594mm; 608mm; 626mm; 678mm |

| Rubber Blanket Length (Narrow): | 587mm; 602mm; 615mm; 630mm; 651mm; 703mm |

| Rubber Blanket thickness with packing: | 2.1mm |

| Rubber Blanket thickness W/O packing: | 1.7mm |

| Printing Length Max.(T-Bar): | 482mm; 507mm; 520mm; 534mm; 552mm; 604mm |

| Printing Length Max (Narrow): | 493mm; 518mm; 531mm; 545mm; 563mm; 615mm |

| Non-Printing gap(T-Bar): | 26mm |

| Non-Printing gap(Narrow): | 15mm |

| Paper Grammage(Uncoated): | 38-100gm/sqm |